Have you heard of Variable Refrigerant Flow (VRF) air conditioning systems? VRF is currently gaining popularity in the United States as we learn more about this efficient cooling and heating method.VRF has been used for years in Asian and European countries since its invention in Japan by Daikin Industries, Ltd. in 1982. This type of system is attractive to property owners seeking high-efficiency cooling systems for their existing or new-construction residences.

So What Makes VRF Unique?

VRF systems handle air differently than conventional HVAC units which blend outside air and return air, cool it in a handler, and force the cooled air through a duct system for distribution through a structure.

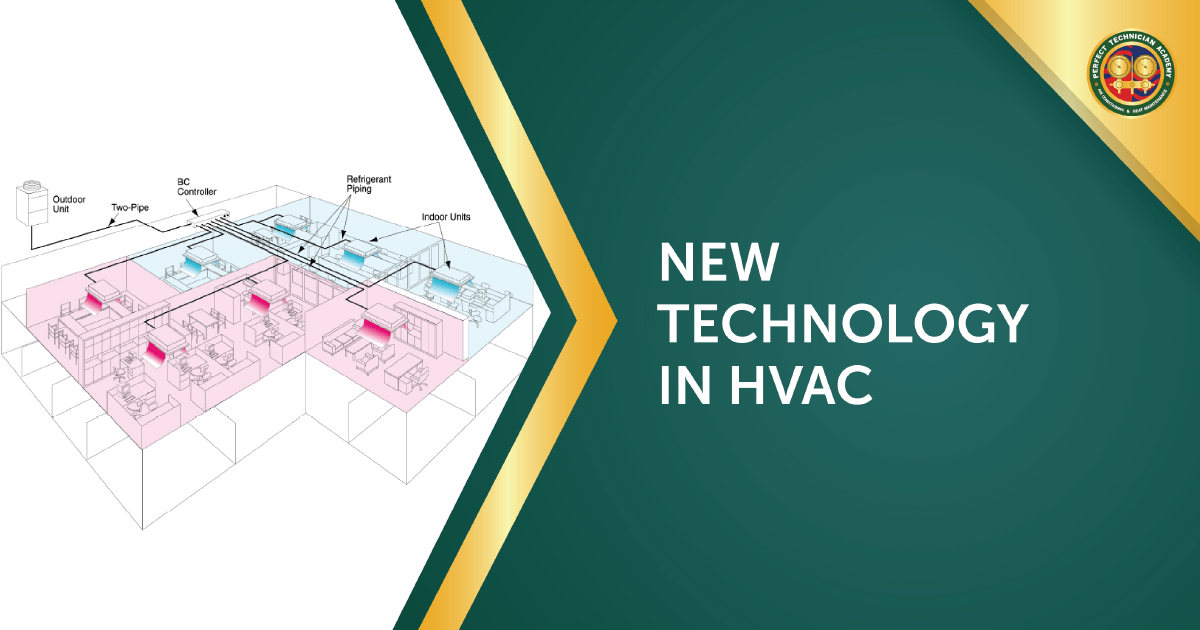

VRF systems make better use of refrigerant and return air by sending refrigerant throughout the building to indoor coil systems and sending it back to a condenser to be repressurized and to release heat when needed — eliminating the need for a condenser altogether.

The system is simply reversed when heat is the goal, making VRF a true all-in-one system. VRF systems can determine the cooling and heating requirements in zone areas and match the refrigerant flow and direction based on zone demands. This tech makes the best possible use of air and energy in a building that requires heat and cooling in different areas simultaneously. VRF systems are a favorite of multi-unit housing landlords, for obvious reasons!

Climates that have mild fall and spring temperatures like the California north coast are ideal for implementing VRF systems. During mild weather, the demand for heating and cooling is typically split between those desiring to be cool and those desiring to be warm. The split demand is handled more efficiently with a VRF system and building owners can reap the rewards of reduced energy consumption.

How Do VRF Systems Work?

VRF systems use smaller duct systems that can be helpful when installing in older buildings that weren’t originally constructed with ducts for conventional HVAC systems or enough interior wall space to accommodate traditional ducting.

The efficiency of air management with VRF systems usually entails ducting outside air directly to the terminal units that can be handled by a smaller ducting system. Smaller ducting means lower renovation costs and minimal effects on the building’s exterior aesthetic which is important for historical structures.

VRF systems are a practical choice for structures that have fixed spaces, such as an apartment building. Fixed spaces set the criteria for zone heating and cooling demands within a VRF and are best suited for static interior architecture.

A commercial building that leases or sells space wouldn’t be well suited for a VRF system because the interior space will be altered repeatedly over the structure’s lifetime to meet the needs of changing tenants. New VRF would have to be installed to accommodate adjustments to the zone demand. Repeated reinstallations would likely drive the cost up enough to consume any energy savings accumulated during use.

It is exciting to welcome different system options into the HVAC industry in the United States. We love to explore and learn about different systems. New technology creates a need for additional education and training to understand, install, repair, and maintain VRF systems as they gain popularity across the 50 States.

Perfect Technician Academy is committed to providing a current, comprehensive curriculum for people who are in, or would like to start, a career in this growing, lucrative industry. With small class sizes and personal instruction, students learn new skills quickly at Perfect Technician Academy.